So what is the difference between Loose Tube and Tight Buffered cables?

Fiber optic cables are the lifeline connection of any fiber optic network and act as the main link between network transceivers, and passive network hardware. What they do is carry light signals between various types hardware. Simply put, they form part of the essential and necessary building blocks of any ICT network.

Plugsters stock a large variety of cables to suit any budget and requirement. Our product line includes a variety of singlemode, multimode, OM1, OM2, OM3 and OM4 options, plus a wide variety of accessories.

One of the most important things to consider when selecting your cables is which cable structure is best suited for the environment in which your network will operate. Some cables are better suited to indoor as opposed to outdoor, and wet conditions as opposed to dry.

When selecting your cables, there are multiple factors to consider. There are generally two main options when looking at cable construction: Tight buffered fiber cables and loose tube buffered cables. Other cable construction types such as micro core, mini tube, ribbon and flexible/rollable ribbon, as well as hybrid cable types are also available and provide other advantages and benefits. This article will focus on 2 main cable types being used – tight buffered fiber optic cables and loose tube fiber optic cables.

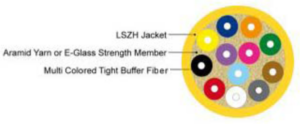

Tight buffered fiber cables are usually constructed with 900um buffered fibers surrounded by aramid yarn or e-glass strength members jacketed in an LSZH outer jacket. They can be used both indoor and outdoor situations and are designed in such a way that the buffering material is in direct contact with the fiber. This structure protects individual fibers during the handling, routing and connecting process.

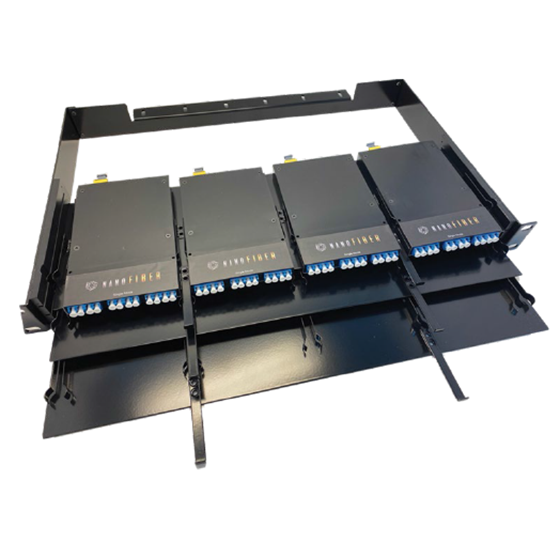

The main use of tight buffered cables, also known as riser cable or fiber distribution cable, is within buildings and are generally installed on cable trays or in conduits. Therefore, they are perfect for internal plant or building networks.

These cables are generally supplied with a LSZH jackets.

There are two main types of tight buffered cable structures, breakout cable (also known as fan-out cables) and distribution cable. The distribution cable design is more compact than the breakout structure, however, the tight-buffered fiber inside the cable are only bundled in a single outer jacket for protection.

Within breakout cables, each simplex cable has its own aramid yarn strength member and jacket. These subunits are wrapped in a polyester tape and sheathed in LSZH. This means that the cable can be broken out into separate simplex cables for individual use. The breakout cables are designed for installations requiring a reliable design in which protection from other mechanics and the environment are required. These cables are some of the easiest to install for direct termination of connectors to sub-units and direct run to panels.

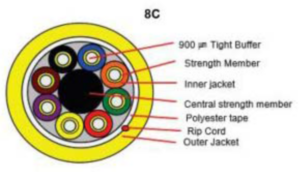

Loose tube optical fiber cables, consist generally of 250 micron fiber core, installed in bundles within a tube. A single tube may consist of 12 individual fibre cores. Each of these 12 fiber tubes may then be bundled with other 12 fiber tubes, to make up a single cable of multiple fiber cores, e.g 12 x 12 fiber tubes = 144 fiber loose tube cable.

This example of a multi loose tube cable, would consists of up to 144, 250μm optical fibers in 12 fiber gel-filled loose tubes. The tube design allows groups of fibers to be dropped-off at different points without interfering with other tubes being routed to separate locations. This cable also generally contains a central strength member to provide more sturdiness to the cable.

Furthermore, the outer sheath and type of material used also provides suitability for external or outside plant use. It features water blocking tape, rodent proofing (e.g. steel wire armored), termite resistance, sacrificial sheaths and many other potential benefits when used in outside or harsh environments.

Loose Tube vs Tight Buffered Cables

Loose tube cables are better suited for outdoor and harsh environments as they secure the fibers within a gel that protects the fibers from water and temperature changes. These types of cables should not be routed through multiple corners or bends as this causes damage to the gel and will result in the core being exposed. Due to the diameter of the of the fibers used in loose tube cables, they generally hold more fibers than tight buffered cables.

On the other hand, tight buffered cables are perfect for indoor use and medium length LAN/WAN connections as they are the sturdier option. Another advantage to tight buffered cables is that they are much easier to install as there is no gel to clean up afterwards and they do not require a fan out-kit for splicing or termination as you can crimp connectors directly to each fiber.

Therefore, it is the application and environment in which the cable is being used, will determine the best cable of choice to use.