Technical Information on Connector Performance

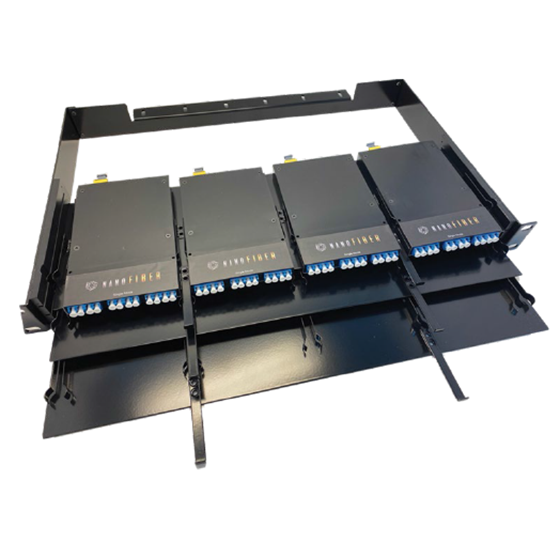

DESCRIPTION

So what is END Face Geometry in Fiber Optics?

Abalone connectors and adapters are subjected to reliability and performance testing in a program including type approval and continuous monitoring. When terminated using best practices, typical optical performance meets or exceeds the stated performance and will meet appropriate standards including IEC61755-3-1/2, ISO/IEC 11801 and TIA/EIA 598.

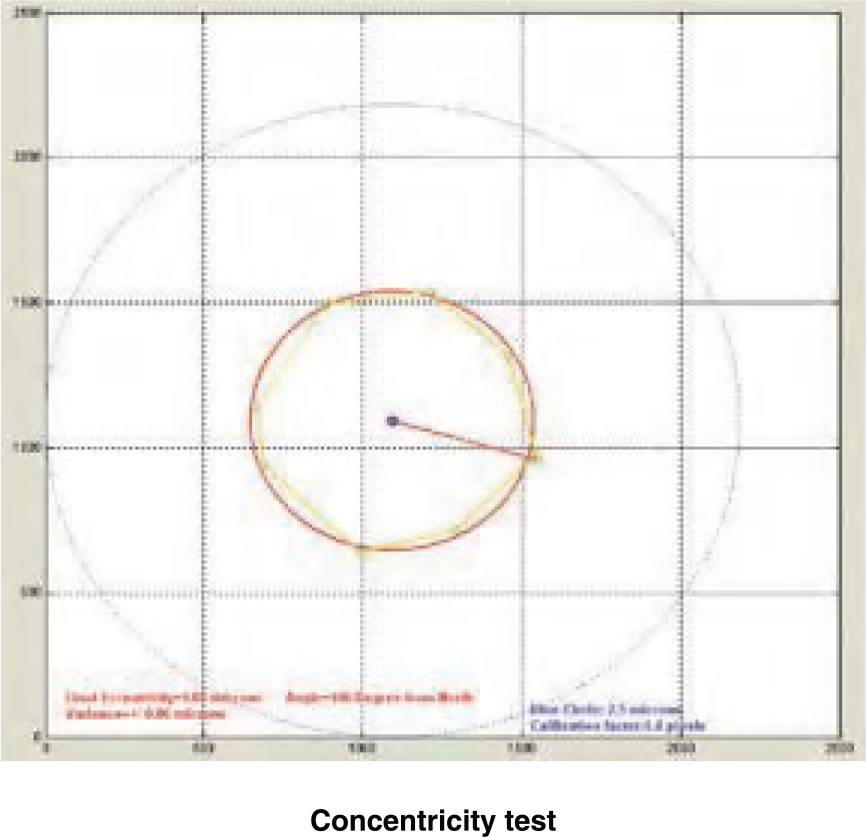

Production quality control procedures monitor all critical parameters including ferrule OD, ID, roundness and concentricity. A unique, in-house developed concentricity test set is used to inspect ferrules and terminated assemblies. Our products conform to LSZH, OFNR, OFNP material classifications and the RoHS directive, REACH SvHC regulations.

Terminated connectors are tested for insertion loss (master lead/random mating) and reflection loss which follows the IEC61300-3-4/34 and IEC 61300-3-6 standards. Abalone manage the complex interaction between the factors including ferrule and fiber dimensions, end face geometry, polish surface finish and axial contact force. The random mating tests give a good indication about the average test results and the worst case performance results which depend on the above factors. The master lead test is used in production line.

End Face Geometry in Fiber Optics

TECHNICAL SPECIFICATION

| Parameter | Criteria |

| RADIUS (PC) | 5-30μ |

| RADIUS (APC) | 5-12μ |

| APEX | 0-70μ |

| UNDERCUT | -100 TO+F(R,A) |

| Optical Performance High Performance Logix Premium Standard Conformance |

| Insertion Loss (Typ) 0.10dB 0.15dB 0.25dB IEC 61300-3-4 |

| Insertion Loss (97%) 0.20dB 0.30dB 0.40dB IEC 61300-3-4 |

| Av/Master 0.08dB 0.12dB 0.18dB IEC 61300-3-4 |

| Av/Random 0.08dB 0.12dB 0.18dB IEC 61300-3-4 |

| Return Loss 55/70dB 55/65dB 55/65dB IEC 61300-3-6 |